Product description

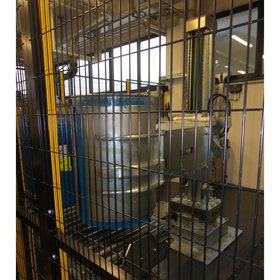

BS103 I is an automated machine for the clamping and emptying of drums (of any type) in tanks or hoppers, for plants where the inlet of full drums and the exit of empty ones is managed by roller conveyors.

Built in sturdy metal structural works to be anchored to the ground (stainless steel or painted with anti-rust and enamel), BS103 I offers a high ease of loading and unloading of drums on the roller conveyors. The clamping jaws, 400/600 mm high, are completely covered with high adhesion rubber (interchangeable) for a better grip and protection of the drums.

All the operations are managed through an electrical panel with PLC to achieve, according to the product to be poured, a wide range of customizations such as the setting of the rotation degrees of the column and of the tilter, the lifting speed of the column and that of the drum rotation and many others. If necessary, the most important operations can also be controlled using the joystick.

At the customer's request, the mixer can be equipped with guards, with safety sensors located on the access doors to the work area.

- Available in both stainless steel and painted steel.

- Tailored solutions - Custom design for your needs.

- Reliable experience - Over 30 years of successes.

- ATEX certification - Possibility to ATEX conversion.

- Customer support - Immediate answers and solutions.

Technical specifications

| Model | BS103 I |

| Tilter | Lateral |

| Capacity | 200 / 1000 kg |

| Power control unit | 4 kW 400V |

| Oil tank | 55 l |

| Drum rotation speed | 4 rpm |

| Gripping range | D 400/600 mm |

| Warranty (years) | 2 |